|

|

| Titan Tubing: We Can Take the Pressure | |

DIE SET Model DXGZ68(Single Phase)HYDRAULIC CRIMPING MACHINE Consist of total 10 sets of Die Set an sizes are: 6mm,8mm,10mm,13mm,16mm,19mm,22mm,25mm,32mm,38mm and 51mm (6mm and 8mm in one set for common usage).

OPERATION MANUAL 1) Before manual or technical operation,skiving the hose outer cover (if it needed)at first; 2) Put the ferrule on the hose outer cover and insert the hose end into the hose inner hole; 3) By operating the machine and swaging die set head to crimp the hose and ferrule,having the hose wire,the ferrule and hose end to be clamped together tightly; 4) The Crimping range should be calculated according to the size of the hose ferrules.For example:The size 1?¡À*4S hydraulic hose,the ferrule outer diameter is 46mm,the crimping range should be about 0.4-0.5mm,and after crimping finished,the standard range should be 42mm-41mm.

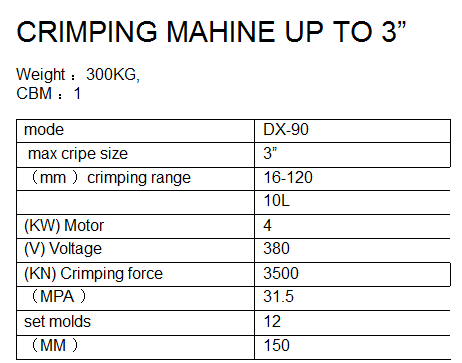

MAIN TECHNICAL SPECIFICATIONS 1) The ferrules materal should be A3 with tensile strength ob38kg/mm2; 2) Standard pressure:31.5Mpa; 3) Working pressure:28.5Mpa; 4) Motor power:220V 2.2KW(Model DX68 Single Phase), 380V 4.0/3.0KW(Model DX69 Three-Phase); 5) Opening time: 220V 2.2KW oil pump flux range 2.5(Swaging for 28 seconds),380V 4.0KW,oil pump flux range 10.0(Swaging for 7 seconds),3.0KW oil pump flux range 5.0(Swaging for 15 seconds).

OPERATION INSTRUCTION 1) For 220-380V electrical power machine,connecting at first the main wire,switching power and the ground wire before operation.(For 220V electrical power machine you must use a spical wire circuit with wire diameter of 2.5mm.To mix usage of recidential electrical power is prohibited.To use 380V electrical power,you should well connect 3 positive wires and 1 220V negative wire. 2) By connecting the electrical power,you should at first turn on the Opening Control Switch to check if it is normal,then turn on the moter switch and push again the button of Opening Switch to keep the machine in a normal working condition,then you can start crimp the hose with ferrules. 3) The machine has the micro switch to control the size of crimping hose.To adjust O to O is the size of swaging inner hole,turn clockwise is for bigger and in contrary is for smaller,ture one round clockwise for 1mm bigger or turn counter clockwise for 1mm smaller. 4) If in case the swaging ahead uncontrollable,shut off the motor power immediately and check the Electromagnetism valve.

EXPEL THE BRKEDOWN 1) Opening and Swaging die set unworkable. Shut off the motor power and plug off the Micro. Switch Plug,try to turn on Opening and Swaging switch buttons continuously in order to normalize the Electromagnetism Valve. If it is still not workable,let loose the 4 pieces of screws for Electromagnetism Valve and use gasoline to clean the inner parts of Electromagnetism Valve. 2) The Motor operations normal,but the Oil Cylinder not workable. Check if 220V wires are connected well,open the Electrical Control Box to check the fuse is broken or not. 3) The swaging in position can not be controlled and without warning. Let loose the Micro Switch and well connect the plug,then push the Spring to see if it is normal.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

© Copyright Titan Tubing, 2008. All Rights Reserved. — Web design by Eyegotch'a Graphics